Expansion project at Davenport Works plant will boost High Purity Aluminum (HPA) capacity for aerospace and defense applications, with funding support from Defense Production Act (DPA) Title III award.

PITTSBURGH, PA, September 26, 2025 – Arconic Corporation (“Arconic” or the “Company”) marked the commissioning of a $57.5 million expansion project at its Davenport Works plant in Iowa on September 25. The project has effectively doubled domestic production of High Purity Aluminum, a critical material to aerospace and defense applications.

The project was supported by an award of $45.5 million from the U.S. Department of War in 2023, utilizing Defense Production Act (DPA) Title III authorities. The Defense Production Act Title III program supports domestic industrial capabilities essential to national security.

Diana Perreiah, Executive Vice President of Rolled Products North America, said, “Arconic is honored to support American leadership in advanced manufacturing by expanding domestic production of High Purity Aluminum for next-generation aerospace and defense applications. This project strengthens critical supply chains and supports national defense priorities, while reinforcing our role as a trusted partner in delivering materials essential to U.S. security and competitiveness.”

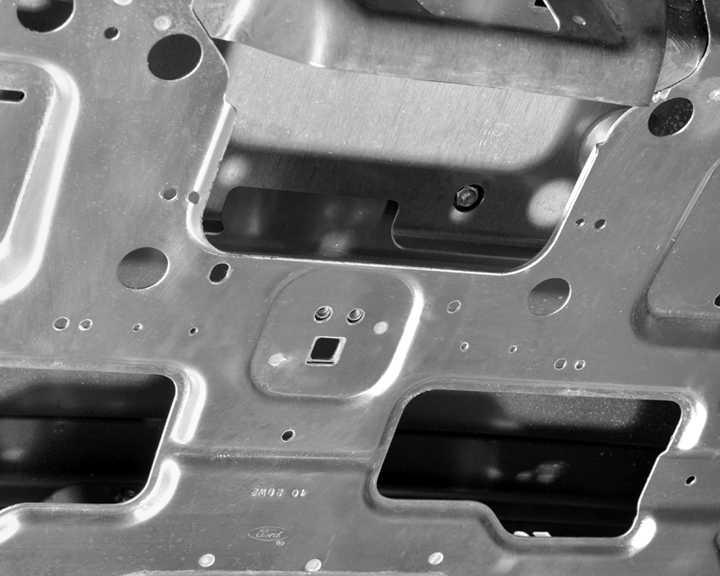

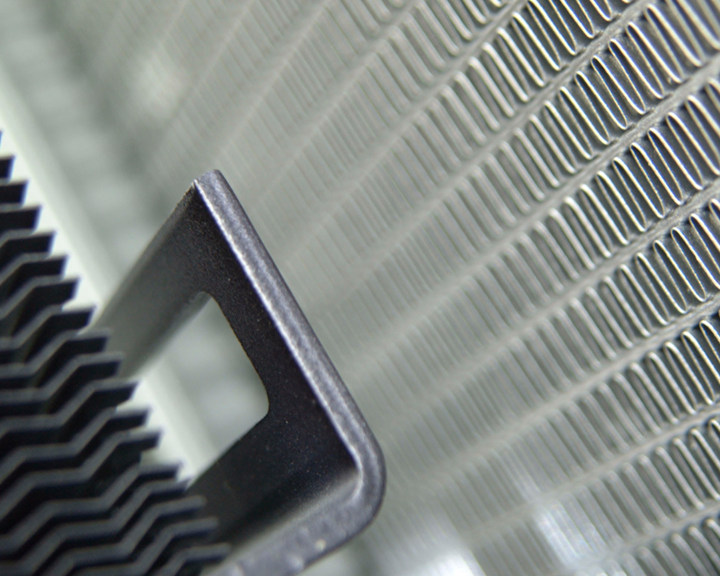

HPA is a type of unwrought, unalloyed aluminum that is characterized as having a minimum purity of 99.9 percent aluminum by mass. HPA is used to produce unique alloys that have strong damage tolerance and resistance to high temperatures, and it is a key input for manufacturing aluminum sheet, plate and extrusions that are used for various aviation, space, and defense applications. Among the defense applications that require HPA are the bulkheads for the F-35 and advanced armor plate for the Joint Light Tactical Vehicle.

The William M. Thornberry National Defense Authorization Act for Fiscal Year 2021 directed the Secretary of Defense to examine how DPA authorities could incentivize domestic aluminum manufacturing and processing. The War Department determined that High Purity Aluminum is critical to national defense due to its role in advanced alloys used in aerospace and ground systems. The HPA expansion project at Arconic Davenport Works directly addresses the identified gaps in domestic HPA capacity by deploying a proprietary production process that offers a more efficient and dependable alternative to smelter-based methods. This approach ensures scalable supply for defense-critical applications.

With the design and installation of two new furnaces and advanced control and automation systems, the project provides the United States surge capacity for HPA production and mitigates potential risks to national security in the event of an industrial mobilization. Key supplier partners to the project include Fluor Corporation and Gillespie & Powers, Inc.

“Delivering this project on schedule and on budget reflects the skill and commitment of our Davenport Works team and the strength of our collaboration with the U.S. government,” said Jeff Weida, Vice President of Manufacturing Davenport Works & Satellite Operations. “This investment expands our advanced aluminum manufacturing capabilities and reinforces Iowa’s role as a hub for high-tech production and industrial innovation.”

At a ribbon-cutting ceremony on September 25, Weida was joined by Iowa Governor Kim Reynolds, Lieutenant Governor Chris Cournoyer, U.S. Senator Joni Ernst, U.S. Representative Mariannette Miller-Meeks, State Representative Gary Mohr, Riverdale Mayor Anthony Heddlesten, Iowa Association of Business and Industry President Nicole Crain, and Quad Cities Chamber of Commerce President and CEO Peter Tokar III to mark the milestone of commissioning the facility. Federal officials who represent Davenport Works and its employees — Iowa Senators Joni Ernst (R-IA) and Chuck Grassley (R-IA), as well as Representatives Mariannette Miller-Meeks (R-IA) and Eric Sorensen (D-IL) — have been long-time supporters of this project.

About Arconic

Arconic Corporation, headquartered in Pittsburgh, Pennsylvania, is a leading provider of aluminum sheet, plate and extrusions, as well as innovative architectural products, that advance the ground transportation, aerospace, building and construction, industrial and packaging end markets. For more information, visit www.arconic.com.

Media Inquiries

MediaInquiries@arconic.com

Investor Relations

Investor.relations@arconic.com

Forward-Looking Statements

This release may contain “forward-looking statements” within the meaning of the U.S. Private Securities Litigation Reform Act of 1995. Forward-looking statements include those containing such words as “anticipates,” “believes,” “could,” “estimates,” “expects,” “forecasts,” “goal,” “guidance,” “intends,” “may,” “outlook,” “plans,” “projects,” “seeks,” “sees,” “should,” “targets,” “will,” “would,” or other words of similar meaning. Forward-looking statements include information concerning our liquidity and our possible future results of operations, including descriptions of our business strategies and the cost savings and other benefits we expect to achieve as a result of the actions discussed herein. These statements reflect beliefs and assumptions that are based on the Company’s perception of historical trends, current conditions and expected future developments, as well as other factors the Company believes are appropriate in the circumstances. Although we believe that the assumptions and analysis underlying these statements are reasonable as of the date hereof, investors are cautioned not to place undue reliance on these statements. Actual Forward-looking statements are not guarantees of future performance, and actual results may differ materially from those indicated by these forward-looking statements due to a variety of risks, uncertainties and changes in circumstances, many of which are beyond the Company’s control, including, among others, the risk factors that are described in our most recent Annual Report, Quarterly Reports and Current Reports. The statements in this presentation and the oral marks made in connection herewith are made as of today’s date, even if subsequently made available by the Company on its website or otherwise. You should understand that these statements are not guarantees of future performance or results. The Company disclaims any intention or obligation to update any forward-looking statements, whether in response to new information, future events, or otherwise, except as required by applicable law.